Bhavna Colourants LLP is located in the financial capital of India. It has manufacturing facilities at multiple locations in Gujarat, in the western part of India, which is known as the chemical hub of India. Some of these facilities are under Contract Manufacturing Agreements.

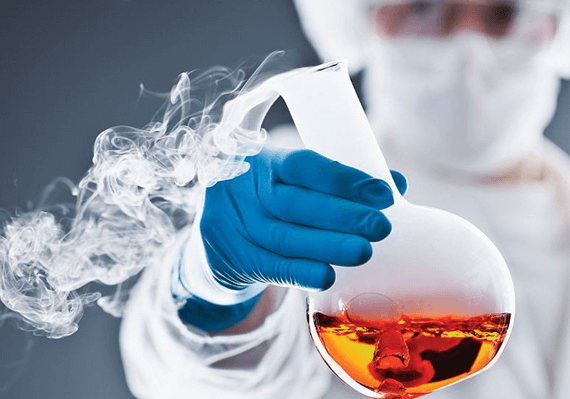

Our State-Of-The-Art manufacturing facility are well equipped with :

§ Skilled work force

§ Latest Machinery

§ Pilot Plant Support System

§ Well-equipped testing application Lab

§ State of Art Packing Line

§ Expert QC team

Bhavna Colourants LLP has a well-equipped centralised state of art testing & application laboratory at its Head Office in Mumbai India.

Our wide range of products are thoroughly tested & approved for desired application by our team of skilled chemists.

This ensures maintaining of stringent quality standards & consistency of supply. Our QC has been a key factor in our success and maintain our continuous growth trend.

Today Bhavna Group has satisfied customers in more than 15 countries.

Our continuous product development & QC has been a driving force tomaintain our consistency in supply & quality standards, thereby giving a sustainable edge of us & our valued customers / Partners even in stringent market conditions.

DM PLANT

Water being an universal solvent, is one of the important factor for uniform results while testing.

To avoid the risk of Contamination and bleeding of dye demineralization process is an important step.

Because the majority of water impurities are dissolved salts the replacement of the mineral salts in water takes place through ion exchange method in DM plant.

PH METER & CONDUCTIVITY METER

The pH and the Conductivity of the solution is monitored and maintained as per Standard Reference/required, to achieve the desired and the uniform results for dying and testing.

SPECTRO PHOTOMETER

• Spectrophotometer used to measures color of dyes solution by transmission mode , evaluates dyeing strength by light reflectance.

• Measures colour by measuring L, a, b value at Illuminant D65, observer at 10 degree.

INFRA COLOUR DYEING MACHINE

• This unit moves the pots in a circular rotation with latest IR heating technology, to avoid uneven heating for pots. Dye-bath temperature is measured directly by a PT-100 probe inside the pot.

• Air cooling system is available, so no need for water source and reduce operation cost

BROOK FIELD VISCOMETER

A viscometer is an instrument used to measure the resistance to flow, i.e. the viscosity of a Pigment dispersion.

PIGMENT MULLER

Pigment Muller is used for measurement of following tests.

• Colour comparison

• Colour strength

• Dispersion ability

• Relative tinting strength

• Grinding to particle size study (pigment hardness)

against known standard reference under identical test conditions

INCUBATOR

Incubator device is used to observe the stability of samples/ Products under controlled both temperature and humidity.

LAB BALL MILL

A ball mill is a type of grinder used to grind and blend materials; It works on the principle of impact and attrition: size reduction is done by impact as the balls drop from near the top of the shell.

EPPENDORF CENTRIFUGE

Centrifugal force created due to the high speed rotation(approx 3500rpm), leads the Insolubles or the suspended particles i.e. the sediment to settle at the bottom of dye solution, separating the substances with difference of density.

ANALYTICAL BALANCE

With accuracy ranging upto the 3rd decimal or 0.001 we have maximum surety and the uniformity of the dye & pigment solution prepared and hence the accurate end results.

Further the outer box ensure minimum / No dusting and avoids the fluctuation due to air currents if any.

HOT AIR OVEN

• The essential functions of oven are following

• Drying : removing the moisture from the specimen and chamber as efficiently as possible.

• Baking: heating a substrate without dehumidifying it.

• Curing: the sample is physically or chemically altered by a slow baking and drying process.

PULP DISINTEGRATOR

• Mechanical treatment in water so that interlaced fibres, which were free in the pulp stock, are again separated from one another without appreciably changing their structural properties

• The term beating denotes a specific type of refining which gives even pulp dyeing.

PAPER MAKING MACHINE

In papermaking, a dilute suspension of fibers in water is drained through a screen, so that a mat of randomly interwoven fibers is laid down. Water is removed from this mat of fibres by pressing and drying to make paper.

UV-VIS SPECTROPHOTOMETER

To determine the concentration of the absorber in a solution. It is necessary to know how quickly the absorbance changes with concentration Identification is done by comparing absorption spectrum with spectra of known compound.

OPEN BATH BEAKER DYEING MACHINE

Open Bath Beaker Dying Machine which is used for dyeing sample of fabric and yarn at high temperature and high pressure. Machine is appropriate for dyeing all type of synthetic fibers like polyester, viscose, nylon, acrylic and acetate.

MULTI POINT MAGNETIC STIRRER

Device that employs a rotating magnetic field to cause a stir bar (also called "flea") immersed in a liquid to spin very quickly, thus stirring it. The rotating field may be created either by a rotating magnet or a set of stationary electromagnets, placed beneath the vessel with the liquid.